Spotlight on Case Hardened Thread Rolling Screws and changes coming to ASME B18.6.3 & SAE J1237

Just make mention of the term, “Hydrogen Embrittlement (HE)” to folks in the fastener industry and you will see eyebrows raise and then furrow. It is a phrase that evokes images of catastrophic failure and costly lawsuits. Fear of HE can lead to escalating costs due to extreme caution in processing products to avoid risk. Rest assured, the Fastener Committees at organizations such as ASME, SAE, ASTM, and ISO do seek out ways to improve fastener standards to minimize risks while keeping an eye out for excessive cost based on fear instead of fact.

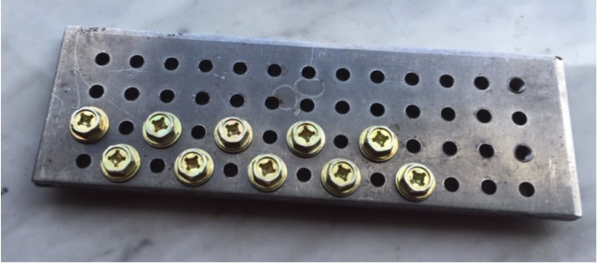

Fastener Committees at SAE and ASME have recently drawn attention to the processing requirements for case hardened tapping and thread rolling screws covered in ASME B18.6.3 and SAE J1237. Product requirement revisions that are being considered include the following:

1) A reduction in the maximum core hardness allowed from HRC 28-38 to HRC 28 – 36.

2) Addition of language to consider the heat treat and HE test requirements for tapping and thread rolling screws that are part of a screw and washer assembly.

Item 1 revisions are based on industry research* that identified that case hardened screws were not inherently susceptible to HE as long as the core hardness was kept below the level at which the screw is prone to HE fracture. The studies confirmed that while embrittlement cracks may form in the hardened case, the cracks did not propagate through the core if the core hardness is properly controlled.

Item 2 revisions, requested by engineers at General Fasteners, addresses the special heat treat and test considerations when a washer is assembled to the case hardened screw. Preferably, the washer is rolled on the screw after it is heat treated or the washer is masked from the carburizing atmosphere prior to heat treat. This is to keep thinner washer sections from becoming prone to brittle fracture due to a lack of a ductile core.

These HE mitigation efforts via consensus standards illustrate this fact: threaded fasteners, first conceived in 400 B.C., are still vital to humankind and continue to evolve through continuous improvement and attention!

*Medcalf, J.S., Thomas, B.G., and Brahimi, S.V., “Hydrogen Embrittlement Susceptibility of Case Hardened Steel Fasteners,” SAE Technical Paper 2018-01-1240, 2018, doi:10.4271/2018-01-1240